In the realm of industrial infrastructure, cooling towers stand tall – quite literally – as iconic symbols of temperature regulation. These towering structures play a critical role in maintaining the operational efficiency of various industrial کولینگ تاور, power plants, and HVAC (Heating, Ventilation, and Air Conditioning) systems. Their significance lies not only in their imposing physical presence but also in their ability to dissipate excess heat generated by industrial processes, ensuring smooth and sustainable operations.

The Anatomy of Cooling Towers

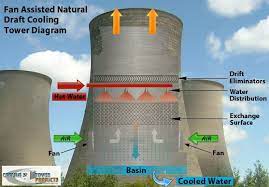

Cooling towers are ingenious structures designed to transfer heat from industrial processes to the atmosphere, thereby cooling water used in various applications. While they come in various shapes and sizes, their basic principle of operation remains consistent across different designs.

At the core of every cooling tower is a large basin filled with water. This water, heated by industrial processes or power generation, is pumped into the tower and distributed over a fill media – usually made of plastic or wood. As the water cascades over the fill media, it increases the surface area exposed to air, facilitating the evaporation process.

Simultaneously, large fans situated at the top of the tower draw ambient air through the fill media. This air, as it comes into contact with the water, absorbs heat through evaporation, thereby cooling the water. The cooled water is then collected in the basin and recirculated back to the industrial process for reuse.

Types of Cooling Towers

Cooling towers come in several configurations, each tailored to suit specific industrial requirements and environmental conditions. The most common types include:

- Natural Draft Cooling Towers: These towers rely on the principle of natural convection for air movement. Their towering height and large chimney-like structures facilitate the upward movement of warm air, drawing in cooler air from the surroundings. Natural draft towers are often used in large power plants and heavy industries due to their high cooling capacity and efficiency.

- Mechanical Draft Cooling Towers: Unlike natural draft towers, mechanical draft towers employ mechanical fans to induce airflow through the tower. These towers can be further classified into two subtypes: a. Induced Draft Cooling Towers: In these towers, fans are situated at the top of the tower, drawing air upwards through the tower fill media. This configuration creates a negative pressure zone within the tower, enhancing airflow and cooling efficiency. b. Forced Draft Cooling Towers: Here, fans are located at the base of the tower, pushing air upwards through the fill media. Forced draft towers are often preferred for applications requiring precise control over airflow and temperature.

- Crossflow and Counterflow Cooling Towers: These classifications refer to the direction of airflow relative to the water flow within the tower. In crossflow towers, air flows horizontally across the fill media, perpendicular to the water flow. In contrast, counterflow towers have air moving vertically upwards, opposite to the downward flow of water. Each configuration offers distinct advantages in terms of efficiency and footprint.

Applications and Environmental Impact

Cooling towers find widespread application across various industries, including power generation, petrochemical processing, HVAC systems, and manufacturing. In power plants, for instance, they play a crucial role in cooling circulating water used in steam turbines, improving the overall efficiency of electricity generation.

Despite their undeniable utility, cooling towers are not without environmental concerns. The large volumes of water consumed for evaporation and drift losses, coupled with the potential for microbial growth and Legionella contamination, pose challenges to water conservation and public health. Additionally, the release of warm water vapor into the atmosphere can alter local microclimates, impacting wildlife habitats and ecosystems.

Future Trends and Innovations

As industries strive for greater efficiency and sustainability, innovations in cooling tower technology continue to emerge. Advancements in materials science have led to the development of more durable and corrosion-resistant tower components, extending their operational lifespan and reducing maintenance costs.

Moreover, the integration of IoT (Internet of Things) sensors and predictive analytics enables real-time monitoring of cooling tower performance, allowing for proactive maintenance and energy optimization. Additionally, the adoption of alternative cooling solutions such as dry cooling systems and hybrid cooling towers holds promise for reducing water consumption and minimizing environmental impact.

Conclusion

Cooling towers stand as marvels of engineering ingenuity, facilitating the efficient dissipation of heat generated by industrial processes. From towering natural draft structures to compact mechanical draft units, these essential components play a vital role in sustaining industrial operations while balancing environmental considerations. As industries continue to evolve, so too will the technology driving these iconic structures, ensuring their continued relevance in the pursuit of sustainable development.